Production support and quality control

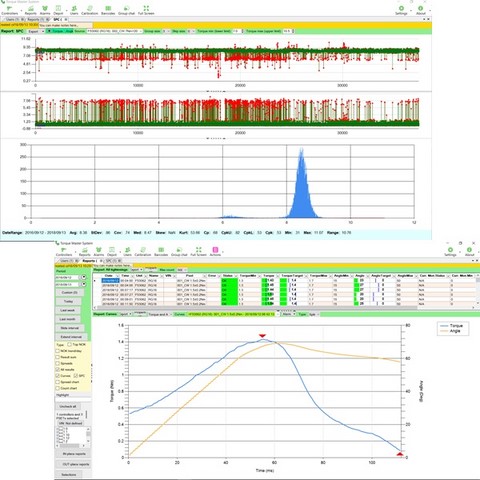

We also support production for tightening technology, but by connecting our TorqueMaster System program to the screwdriver controllers at our customer's factory, we can also provide production support with remote monitoring for your screwdriving processes. The system also indicates starting screw errors, and we can remotely fine-tune tightening parameters to avoid further production problems.

The system also collects data during screwing, including tightening curves, which can be used to detect technological or even screw material defects.

You can count on us for random or constant quality control of your bolted joints. Screws, joints can also be checked with torque measuring arms or ultrasonic measurement.

For application-specific screw joint design, we can also determine the screw to be used and the tightening parameters to save you money.

Other measurements, usually for quality control purposes, can be performed as follows.

The system also collects data during screwing, including tightening curves, which can be used to detect technological or even screw material defects.

You can count on us for random or constant quality control of your bolted joints. Screws, joints can also be checked with torque measuring arms or ultrasonic measurement.

For application-specific screw joint design, we can also determine the screw to be used and the tightening parameters to save you money.

Other measurements, usually for quality control purposes, can be performed as follows.

Screw, joint measurement

Measurement range:

0,5 - 1000 Nm

We have torque arms up to 1000 Nm for torque and angle measurement, which can be used to retrospectively check screw connections without damaging the screw connection or significantly altering the tightening torque of the screw.

Ultrasonic bolt load measurement

Measurement range (bolt length):

max 300 mm

Measuring ultrasonic screw load by ultrasonics, it is possible to determine not only the elongation of the screw due to the tightening, but also the clamping force and the tension in the material of the screw without breaking or changing the joint in any way.